Flying Co2 Laser Marking And Engraving Machine

Product Display

Technical parameter

| Application | Laser Marking | Applicable Material | Non-metals |

| Laser Source Brand | DAVI | Marking Area | 110*110mm/175*175mm/200*200mm/300*300mm/other |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP,ETC | CNC or Not | Yes |

| Wavelength | 10.3-10.8μm | M²-beam quality | ﹤1.5 |

| Average power range | 10-100W | Pulse frequency | 0-100kHz |

| Pulse energy range | 5-200mJ | Power stability | ﹤±10% |

| Beam pointing stability | ﹤200μrad | Beam roundness | ﹤1.2:1 |

| Beam diameter (1/e²) | 2.2±0.6mm | Beam divergence | ﹤9.0mrad |

| Peak effective power | 250W | Pulse rise and fall time | ﹤90 |

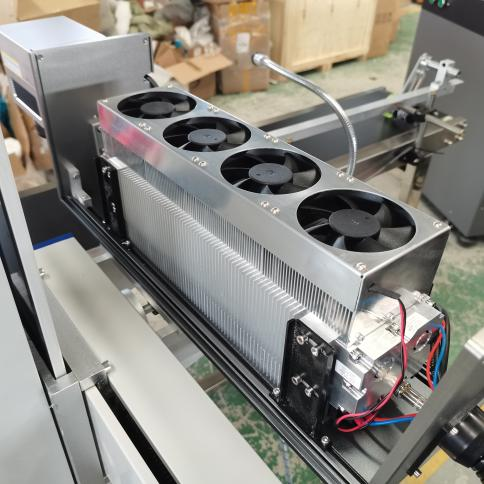

| Certification | CE, ISO9001 | Cooling system | Water cooling |

| Mode of Operation | Continuous | Feature | Low maintenance |

| Machinery Test Report | Provided | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 3 years |

Machine Video

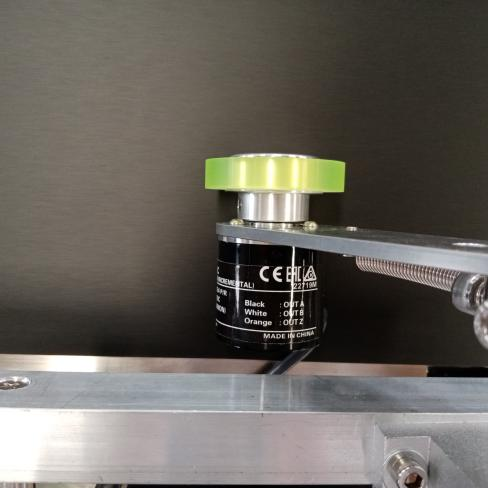

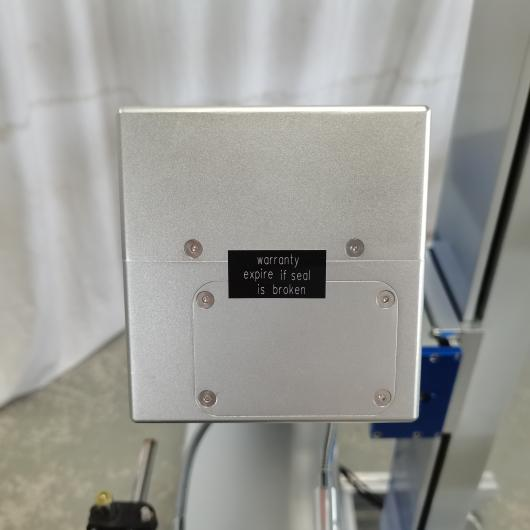

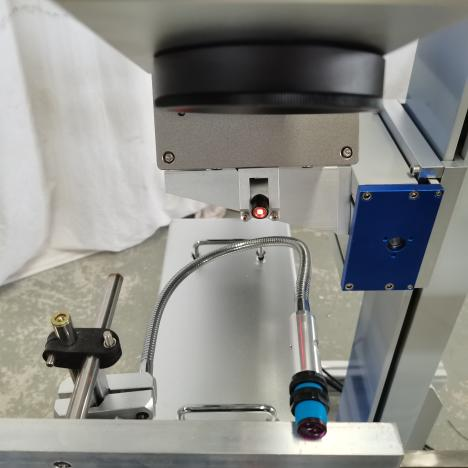

Main Parts for Machine :

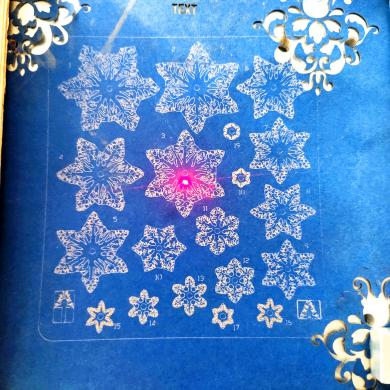

Marking samples :

Service:

1.Customized services:

We provide customized Co2 laser marking machines, custom designed and manufactured according to customer needs. Whether it is marking content, material type or processing speed, we can adjust and optimize it according to the customer's specific requirements.

2.Pre-sales consultation and technical support:

We have an experienced team of engineers who can provide customers with professional pre-sales advice and technical support. Whether it's equipment selection, application advice or technical guidance, we can provide fast and efficient help.

3.Quick response after sales

Provide fast after-sales technical support to solve various problems encountered by customers during use.

FAQ:

Q: What is the difference between a flying laser marking machine and a static marking machine?

A: A flying laser marking machine is suitable for online marking on the assembly line, and the product can be marked while moving; while a static marking machine requires the product to be stationary before marking, which is suitable for small batches or manual loading and unloading scenarios.

Q: Will it affect the surface of the product?

A: CO₂ laser is a thermal processing method, which will not cause structural damage to most non-metallic materials. The marking is clear, beautiful, and does not affect the use function.

Q: Does it support automatic loading and unloading?

A: Optional automatic loading and unloading mechanisms, rotating fixtures, positioning platforms, etc. can be used to meet the needs of automated production.

Q: How deep is the marking depth of the CO2 laser marking machine?

A: The marking depth of the CO2 laser marking machine depends on the type of material and the laser power. Generally speaking, it is suitable for shallow marking, but for harder materials, the marking depth will be relatively shallow. High-power lasers can achieve a certain depth of engraving.

Q: Is the maintenance of the CO2 laser marking machine complicated?

A: The maintenance of the CO2 laser marking machine is relatively simple. It mainly requires regular cleaning of the optical lens, inspection of the laser tube and the heat dissipation system to ensure the normal operation of the machine. Proper daily maintenance can extend the service life of the equipment.

Q: How to choose the right CO2 laser marking machine model?

A: When choosing the right model, you need to consider factors such as marking materials, marking speed, accuracy requirements, equipment power and budget. If you are not sure, you can consult the supplier to make recommendations based on specific needs.