Fiber Laser Cutting Machine

-

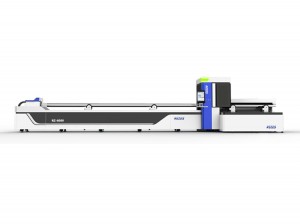

12m Three-Chuck Automatic Feeding Tube Laser Cutting Machine

This equipment is a high-end intelligent equipment designed for long tube laser cutting, supporting high-precision, high-efficiency and fully automatic cutting of tubes up to 12 meters in length. Equipped with a three-chuck structure and automatic feeding system, it greatly improves the stability, clamping flexibility and processing efficiency of long tube processing.

-

4020 Bilateral gantry loading and unloading robotic arm

This system consists of a set of composite truss manipulators for loading and unloading laser cutting machines, a double-layer electric exchange material car, a CNC control system, a vacuum control system, etc., which together with the laser cutting machine form a sheet metal automation production unit. It can realize the task of automatic loading and unloading of plates, effectively improve production efficiency and reduce production costs.

-

6012 Laser Tube Cutting Machine with Side Mount Chuck-3000W

The 6012 side-mounted tube cutting machine is a fiber laser cutting machine specially used for cutting metal tubes. It uses a 3000W fiber laser and is suitable for a variety of metal materials, such as carbon steel, stainless steel, aluminum alloy, copper, etc. This model is equipped with an effective cutting length of 6000mm and a chuck diameter of 120mm, and adopts a side-mounted chuck design to improve clamping stability and cutting accuracy. It is an ideal choice for the tube processing industry.

-

Ultra-Large Format Sheet Metal Fiber Laser Cutting Machine

1.Ultra large metal laser cutting machine is a machine with super large working table. It is specially used for cutting metal sheet .

2.The “ultra-large format” refers to the machine’s ability to handle large sheets of material, with a maximum length of up to 32m and a width of up to 5m. It is commonly used in industries such as aerospace, steel structure, and construction, where precision cutting of large parts is required. It allows for faster and more precise cutting, making it a popular choice for industrial applications.

3.Ultra large metal laser cutting machine adopts the most sophisticated Germany IPG laser, combining high strength welding body designed by our company, after high temperature annealing and precision machining by large CNC milling machine.

4.Laser Light Curtain for Personal Protection

A super-sensitive laser screen is installed on the beam to immediately stop the equipment when someone enters the processing area by mistake, quickly avoiding danger.

-

1390 High precision cutting machine

1. RZ-1390 high-precision laser cutting machine is mainly for high-speed and high-precision processing of metal sheets.

2. The technology is mature, the whole machine runs stably, and the cutting efficiency is high.

3. Good dynamic performance, compact machine structure, sufficient rigidity, good reliability and efficient cutting performance. The overall layout is compact and reasonable, and the floor space is small. Since the floor area is about 1300*900mm, it is very suitable for small hardware processing factories.

4. What’s more, compared with the traditional bed, its high cutting efficiency has been increased by 20%, which is suitable for cutting various metal materials.

-

Full Cover Steel Sheet Metal fiber laser cutting machine price 6kw 8kw 12kw 3015 4020 6020 aluminum laser cutter

1.Adopt fully enclosed constant temperature laser working environment, making sure the stable work more effective.

2.Adopt industrial heavy duty steel welding structure,under heat treatment,will not deform after long time using.

3.Fiber Laser Cutting Machine adopts the most sophisticated Germany IPG laser, combining Gantry CNC machine designed by our company and high strength welding body, after high temperature annealing and precision machining by large CNC milling machine.

-

Affordable Metal Pipe and Tube Fiber Laser Cutting Machine for Sale

1. The two-way pneumatic chuck tube automatically locates the center, extends the transmission structure to improve stable operation,and increases the jaws to save materials.

2.The ingenious separation of the feeding area, the unloading area and the pipe cutting area is realized, which reduces the mutual interference of different areas, and the production environment is safe and stable.

3.The unique industrial structure design gives it maximum stability and higher vibration resistance and damping quality. The compact spacing of 650mm ensures the agility of the chuck and the stability during high-speed driving.

-

High precision fiber laser cutting machine cutting gold and silver

High precision cutting machine is mainly used for gold and silver cutting. It adopts high-precision module structure to assure good cutting effect. The laser source for this machine apply top world import brand, and has stable performance. Good dynamic performance, compact machine structure, sufficient stiffness and good reliability. The overall layout is compact and reasonable, and the floor area is small.

-

Metal Sheet Fiber Laser Cutting Machine

Metal fiber laser cutting machine is mainly used for cutting carbon steel, stainless steel,aluminum alloy, titanium alloy,galvanized plate, copper and other metal materials.Widely used in electrical power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, lighting hardware, display equipment, precision components, metal products and other industries.

-

Whole Cover Laser Cutting Machine

1. Adopt fully enclosed constant temperature laser working enviroment, makig sure the stable work more effective.

2. Adopt industrial heavy duty steel welding structure,under heat treatment,will not deform after long time using.

3. Owned the Japaness advanced cutting head controlling technology, and the automatic failure alarming protective display function for cutting head, using more safely, more convenient for adjustment, an cutting more perfect.

4. Fiber Laser Cutting Machine adopts the most sophisticated Germany IPG laser, combining Gantry CNC machine designed by our company and high strength welding body, after high temperature annealing and precision machining by large CNC milling machine.

5. High efficiency,fast cutting speed.photoelectric conversion rate about 35%.

-

Double Platform Metal Sheet & Tube Fiber Laser Cutting Machine

1. Our fiber laser cutting machine adopts the special CNC system of CypCut fiber laser cutting machine of Windows operating system. It integrates many special functions modules of laser cutting control, powerful and easy to operate.

2. The equipment can be designed to cut any pattern as needed, and the cutting section is smooth and flat without secondary processing.

3. Efficient and stable programming and control system, easy to operate, user-friendly, support a variety of CAD drawing recognition, high stability, with the use of wireless controller.

4. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. -

Metal Tube & Pipe Laser Cutting Machine

1.High rigidity heavy chassis, reducing the vibration generated during the high-speed cutting process.

2.Pneumatic Chuck Design:The front and rear chuck clamping design is convenient for installation, labor-saving, and no wear and tear. Automatic adjustment of the center, suitable for various pipes, high chuck rotation speed, can improve processing efficiency.

3.Drive System: Adopts imported bilateral gear-gear stripe transmission, imported linear guide, and imported double servo motor drive system, import high-precision linear module, to effectively guarantee the cutting speed and high precision.

4.The X and Y axes adopt high-precision servo motor, German high-precision reducer and rack and pinion. The Y-axis adopts double-drive structure to greatly improve the motion performance of the machine tool, and the acceleration reaches 1.2G, which ensures the high efficiency operation of the whole machine.