Frequency conversion speed regulating magnetic polishing machine

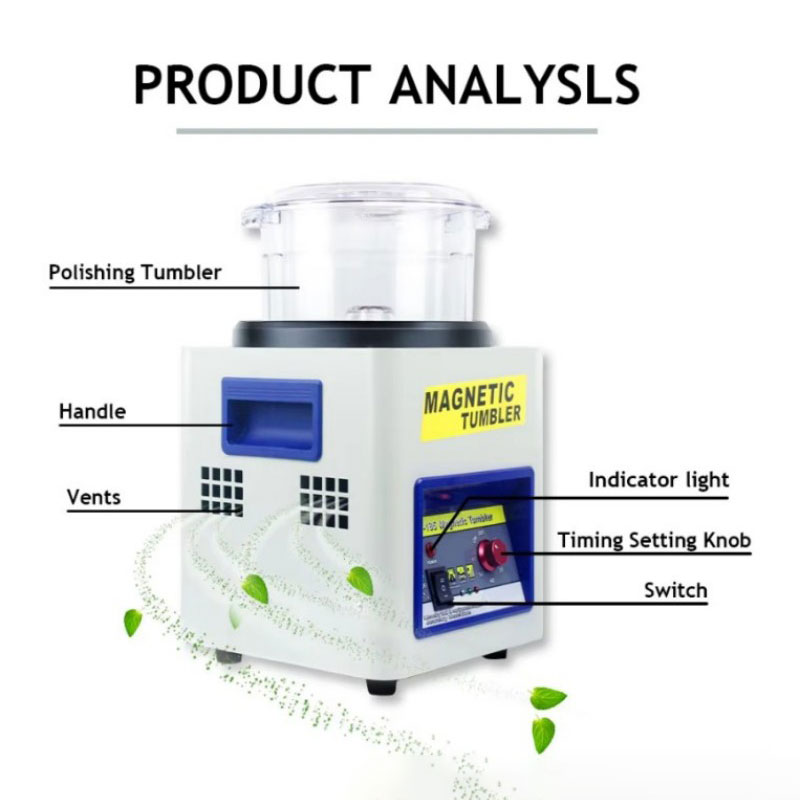

Product Display

Technical parameter

| Product name | 5KG magnetic force machine | Polishing weight | 5KG |

| Voltage | 220V | Polishing Needles Dosage | 0-1000G |

| Speed minute | 0-1800 R/MIN | Power | 1.5KW |

| Machine weight | 60KG | Dimensions(mm) | 490*480*750 |

| Certification | CE, ISO9001 | Cooling system | Air cooling |

| Mode of Operation | Continuous | Feature | Low maintenance |

| Machinery Test Report | Provided | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 1 years |

Machine Video

The characteristic of Frequency conversion speed regulating magnetic polishing machine

1. Frequency conversion speed regulation: the speed can be adjusted according to different processing requirements to improve processing accuracy and stability;

2. High efficiency: a large number of small workpieces can be processed at the same time, and the efficiency is much higher than manual or traditional drum polishing;

3. No dead angle processing: the magnetic needle can enter the holes, seams, grooves and other small positions of the workpiece to achieve all-round polishing;

4. Environmental protection and energy saving: no chemical corrosive liquid is used, low noise, easy operation;

5. Low maintenance cost: the equipment has a simple structure, strong stability, and convenient daily maintenance;

6. Good processing consistency: the surface consistency of the processed workpiece is high, which is suitable for mass production.

Service

1.Customized services:

We provide customized Frequency conversion speed regulating magnetic polishing machine, custom designed and manufactured according to customer needs. We can adjust and optimize it according to the customer's specific requirements.

2.Pre-sales consultation and technical support:

We have an experienced team of engineers who can provide customers with professional pre-sales advice and technical support. Whether it's equipment selection, application advice or technical guidance, we can provide fast and efficient help.

3.Quick response after sales

Provide fast after-sales technical support to solve various problems encountered by customers during use.

FAQ

Q: What materials are suitable for this magnetic polishing machine?

A: The magnetic polishing machine is suitable for metal materials such as stainless steel, copper, aluminum, titanium alloy, and can also process some hard plastic workpieces.

Q: How big a workpiece can be processed?

A: The magnetic polishing machine is suitable for processing small, precision parts (usually no larger than the size of the palm), such as screws, springs, rings, electronic accessories, etc. Workpieces that are too large are not suitable for magnetic needles to enter. It is recommended to use other equipment such as drum polishing machines.

Q: Can it be polished into holes or grooves?

A: Yes. The magnetic needle can penetrate into the holes, slits, blind holes and other parts of the workpiece for all-round polishing and deburring.

Q: How long is the processing time?

A: Depending on the material of the workpiece and the degree of surface roughness, the processing time is generally adjustable from 5 to 30 minutes. The frequency conversion speed regulation system can achieve a more efficient processing effect.

Q: Is it necessary to add chemical liquid?

A: No corrosive chemical liquid is required. Usually, only clean water and a small amount of special polishing liquid are needed. It is environmentally friendly, safe and easy to discharge.

Q: Is the magnetic needle easy to wear out? How long is the service life?

A: The magnetic needle is made of high-strength alloy with good wear resistance. Under normal use conditions, it can be used for 3 to 6 months or even longer. The specific life depends on the frequency of use and the material of the workpiece.

Q: Is the equipment noisy? Is it suitable for office or laboratory use?

A: The equipment has low noise during operation, usually <65dB, which is suitable for use in offices, laboratories, and precision workshops, and does not affect the normal working environment.

Q: How to maintain and maintain it?

A:- Clean the working tank after each use to prevent residue accumulation;

- Check the wear of the magnetic needle regularly;

- Check the motor, inverter, and line connection every month to see if they are normal;

- Keep the machine dry and ventilated to avoid water vapor corrosion of electronic components.