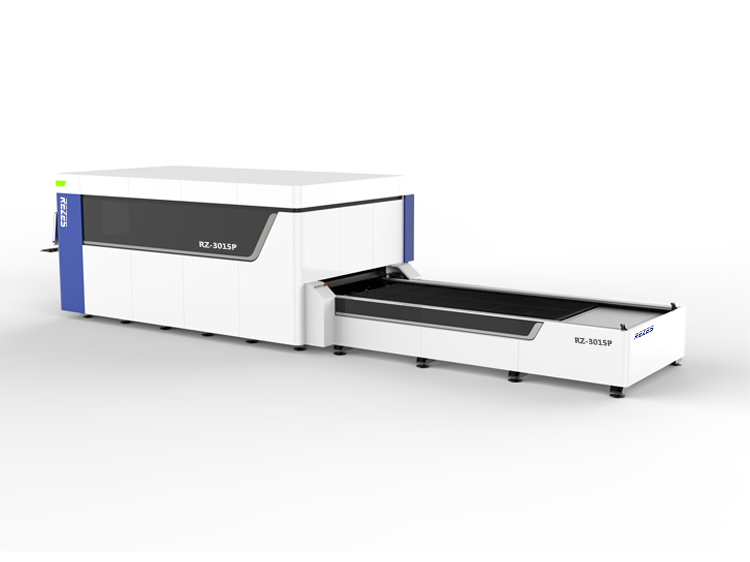

Good Quality Cnc - LASER MARKING MACHINE PART—MAX LASER SOURCE – Rezes

Good Quality Cnc - LASER MARKING MACHINE PART—MAX LASER SOURCE – Rezes Detail:

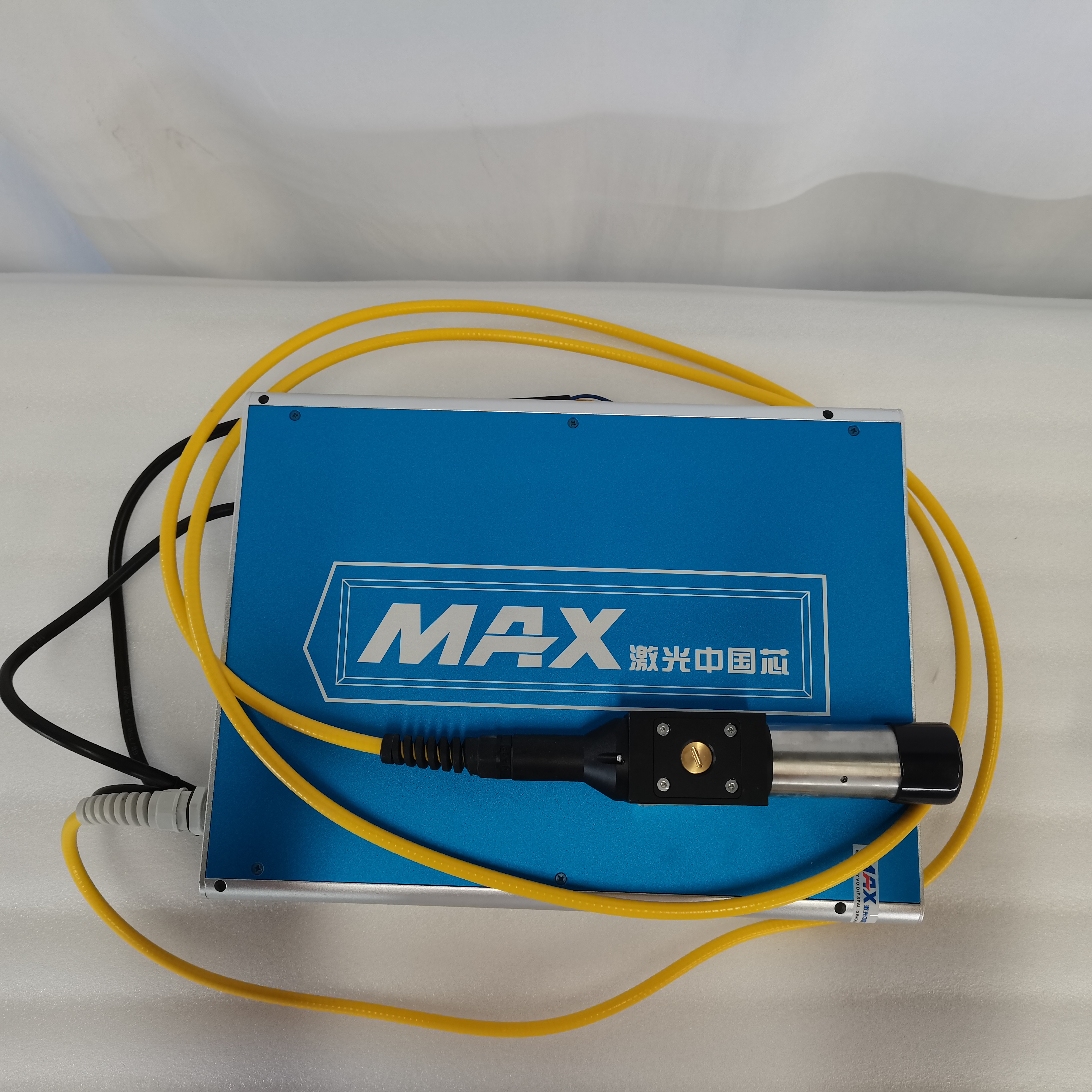

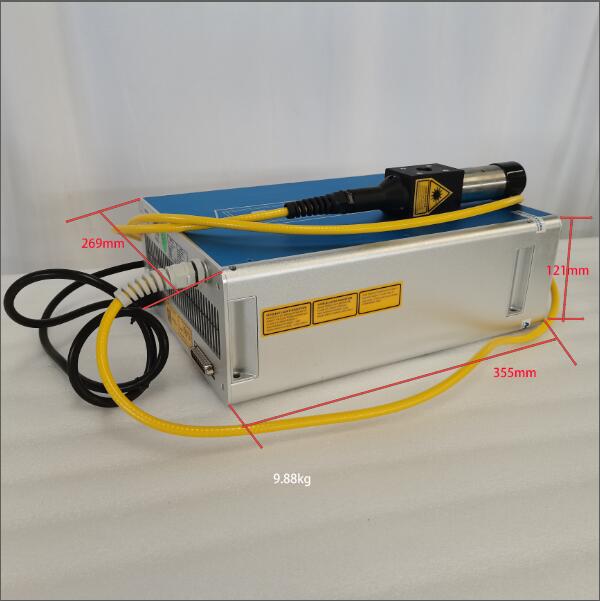

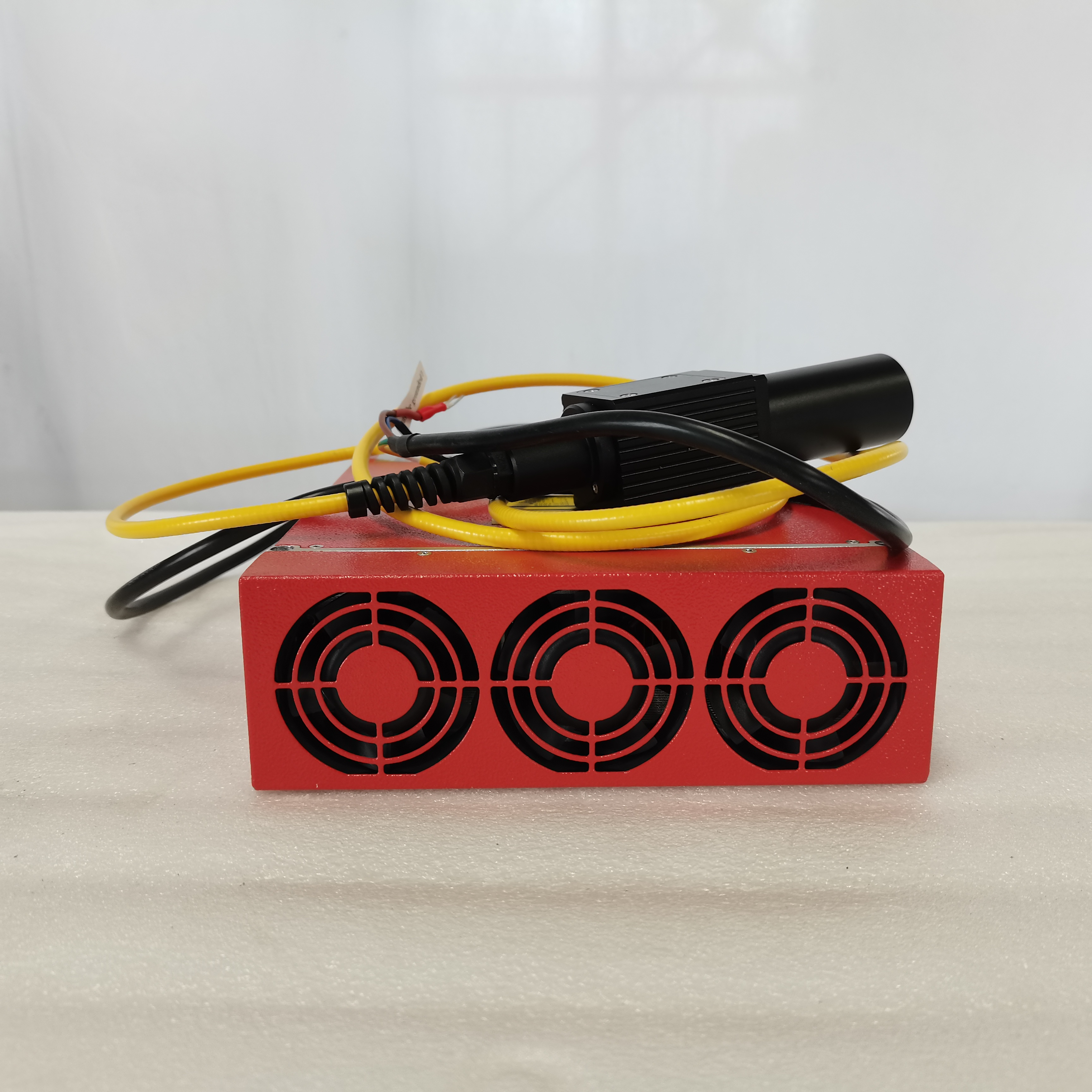

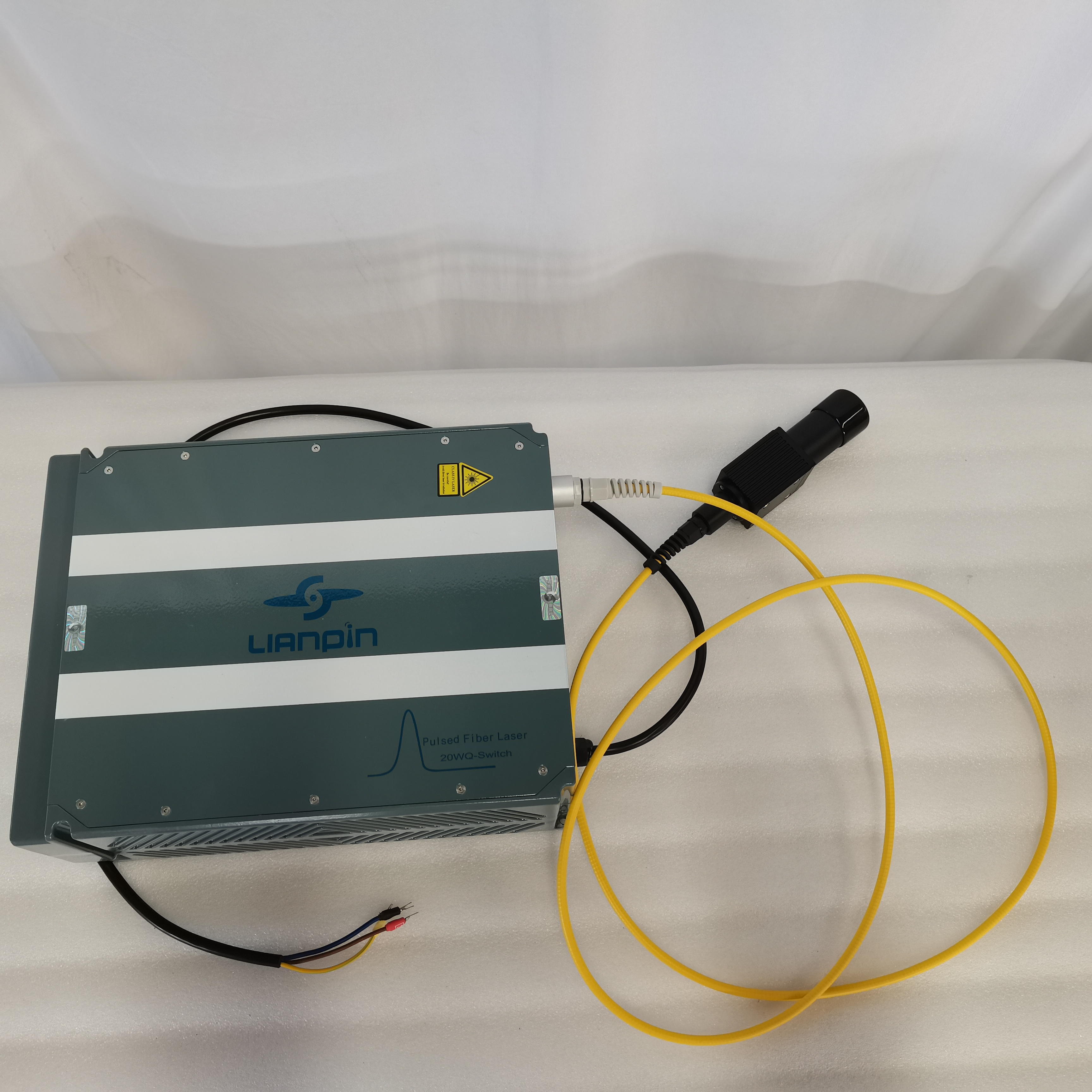

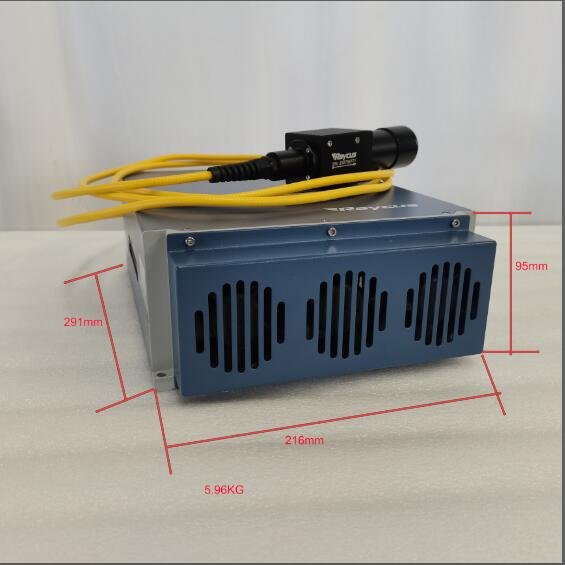

Product Display

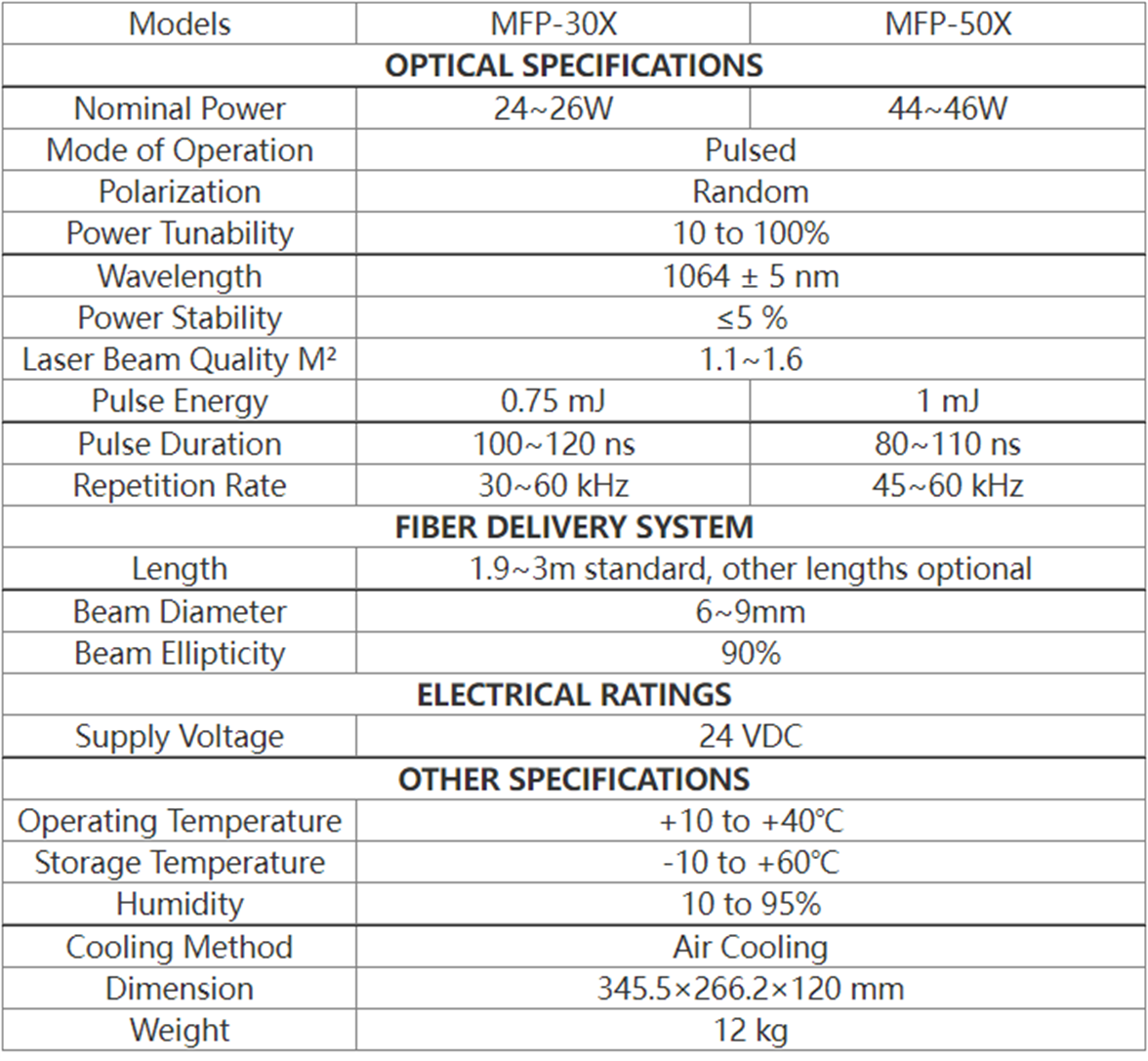

Main parameter

Application:

-

-

- Marking :

Pulsed fiber laser is an ideal choice for marking electronic consumer goods and industrial products. It has the advantages of good marking quality, fast speed and high flexibility. It can be used for quality control and traceability, anti-counterfeiting, product identification, etc.

The laser used by Maxphotonics for marking has good beam quality (M2<1.3) and finer marking effect; wide pulse width (2-350ns), suitable for more materials; wide frequency range (1-2000KHz), marking higher efficiency.

- Deep marking:

Laser deep marking has the advantages of no pollution, high precision, flexible engraving content, and can meet complex engraving processes. It can be used for mark on industrial, machinery and aerospace devices.

Maxphotonics is the laser used for deep marking, with high single-pulse energy (>1.5mJ), strong deep engraving ability and higher efficiency; high power (>200W), deeper engraving depth; good beam quality and fine deep engraving shading

- Cleaning:

Laser cleaning has been widely used in industry, including mold cleaning, rust removal of equipment parts, rust removal of high-speed rail tracks, and gear decontamination.

The laser used by Maxphotonics for cleaning has high single-pulse energy (>30mJ) and higher cleaning efficiency; high power (up to 500W), which can clean thicker rust layers; even spot energy distribution, cleaning does not hurt the substrate.

- Welding:

Pulse fiber laser welding is mainly used for spot welding and seam welding of thin metal materials. By controlling the parameters such as the waveform, width, peak power and repetition frequency of the laser pulse, a good connection is formed between the workpieces.

Maxphotonics laser precision welding laser, the pulse width can be adjusted (1-350ns), which can adapt to the welding of different metal materials; the pulse width is smaller, the frequency is wider, the welding is basically spatter-free, more flat, and the welding is firm.

- Cutting:

Maxphotonics laser for precision cutting has good beam quality, less thermal effect on the slit, no heat deposition, smooth cutting edge without burrs; high peak power (>15kW), fast cutting speed, smooth cutting material and not easy to deform

-

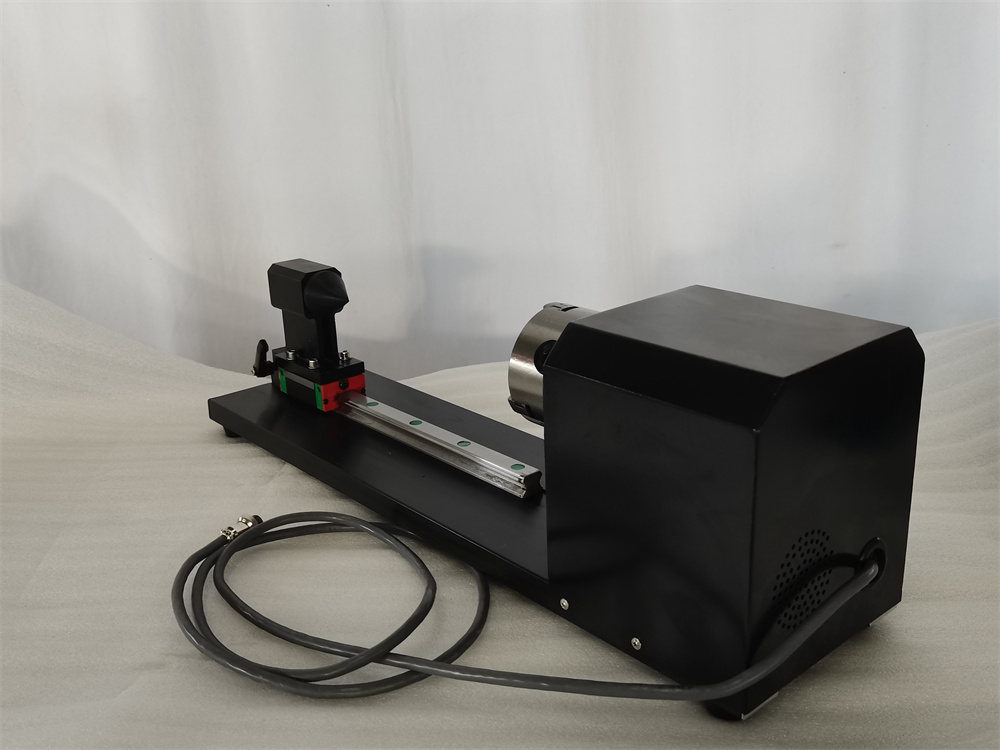

Other Option of rotary device

JPT LASER SOURCE

SUPER LASER SOURCE

RAYCUS LASER SOURCE

Product detail pictures:

Related Product Guide:

We stay with our company spirit of Quality, Performance, Innovation and Integrity. We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Good Quality Cnc - LASER MARKING MACHINE PART—MAX LASER SOURCE – Rezes , The product will supply to all over the world, such as: Egypt, Kuala Lumpur, Israel, As operation principle is be market-oriented , good faith as principle, win-win as objective, holding on customer first, quality assurance, service first as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.