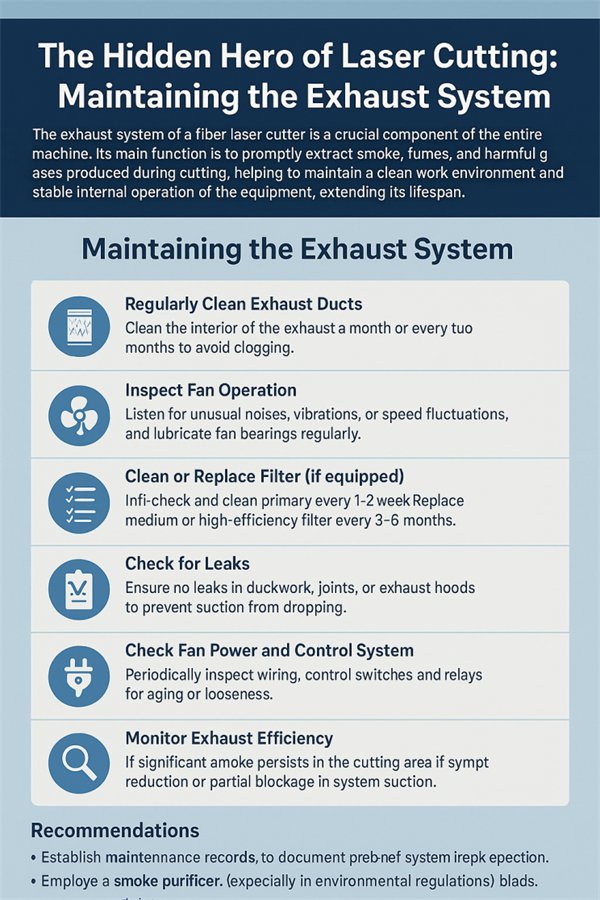

The exhaust system of the fiber laser cutting machine is a very important part of the whole equipment. Its main function is to extract smoke, exhaust gas, harmful gas, etc. generated during the cutting process in time to keep the working environment clean and the equipment running stably, and extend the service life of the equipment.

1. Maintenance method of exhaust system:

1. Clean the exhaust duct regularly

Clean the dust attached to the inner wall of the exhaust duct once a month or every two months to avoid blockage.

2. Check the operation of the fan

Listen to whether the sound is normal, whether there is vibration or abnormal speed; the fan bearing needs to be lubricated regularly.

3. Clean the filter or replace the filter element (if equipped with purification equipment)

* Primary filter: It is recommended to check and clean every 1-2 weeks.

* Medium or high efficiency filter element: Replace every 3-6 months according to the frequency of use.

4. Check the sealing

Ensure that there is no leakage in the air duct, joints, and exhaust hood to avoid a decrease in suction force.

5. Check the fan power supply and control system

Regularly check whether the wiring, control switch, relay, etc. are aging or loose.

6. Monitor the exhaust efficiency

If the smoke residue in the cutting area is serious, it is necessary to check whether the system suction force is reduced or partially blocked in time.

2. Suggestions:

Establish equipment maintenance files to record each exhaust system inspection and maintenance.

Use a smoke purifier (especially in areas with strict environmental protection requirements).

Operator training: Let the operators understand the hazards of smoke and the importance of the exhaust system, and consciously maintain it.

Post time: Jun-11-2025