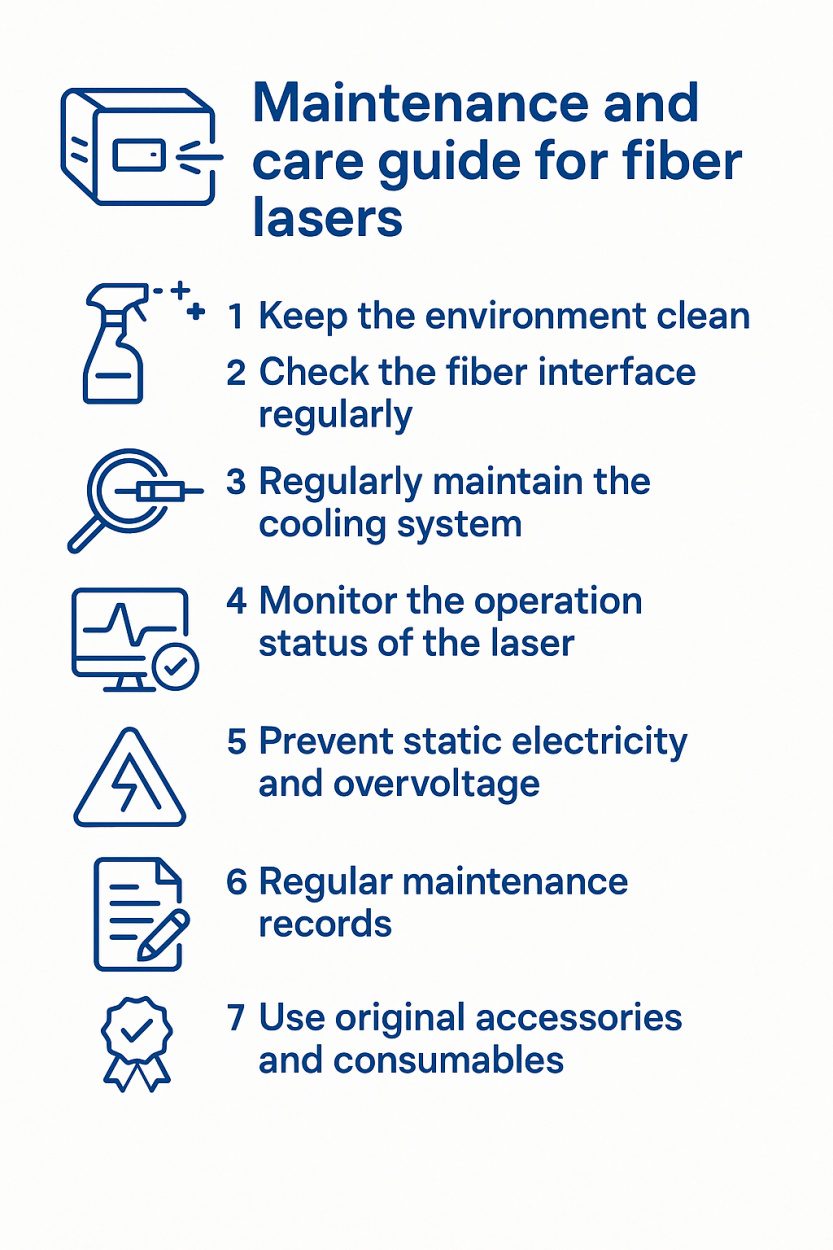

To ensure the stable operation of fiber lasers, extend their service life, and reduce the failure rate, please follow the following maintenance and care points:

1. Keep the environment clean

Keep the laser working environment dust-free, dry, and well ventilated;

The ambient temperature is recommended to be controlled at 15°C~30°C, and the humidity is less than 70%.

2. Check the fiber interface regularly

Use professional cleaning tools to clean the fiber head before and after each connection or removal.Prevent contamination of the fiber end face and burn the core components of the laser.

3. Regularly maintain the cooling system

Check the cooling water quality, water level, and whether there are impurities or algae once a month.

Replace pure water or special coolant regularly (usually once every 3\~6 months).

Ensure that the waterway is unobstructed and the water pipe is not aging or broken.

4. Monitor the operation status of the laser

Regularly check the operation log and alarm record in the laser software.

If abnormal parameters, power attenuation or frequent alarms occur, please contact the manufacturer's technical support in time.

5. Prevent static electricity and overvoltage

Good grounding, the laser housing must be reliably grounded.

It is forbidden to plug or unplug the communication or power cord while it is powered on.

6. Regular maintenance records

It is recommended to establish equipment maintenance files to record the time of cleaning, maintenance, replacement of consumables, etc.

7. Use original accessories and consumables

During maintenance, please use the original accessories and consumables recommended by the manufacturer to avoid compatibility issues.

By referring to the above maintenance and care suggestions, it is helpful to improve the operating stability of the fiber laser, extend the service life of the equipment, and reduce the risk of failure to a certain extent. It is recommended that operators conduct regular inspections, standardize use, and contact the manufacturer's technical support in a timely manner when necessary to ensure that the equipment is always in good working condition.

Post time: Jun-03-2025