12m Three-Chuck Automatic Feeding Tube Laser Cutting Machine

Product Display

Technical parameter

| Application | Laser Cutting Tube | Applicable Material | Metal Materials |

| Laser Source Brand | Raycus/MAX | Number of chucks | Three chucks |

| Maximum pipe length | 12 M | Repeated positioning accuracy | ≤±0.02mm |

| Pipe shape | Round tube, square tube, rectangular pipes,special-shaped pipes,other | Electrical Source (Power Demand) | 380V/50Hz/60Hz |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, DXP,ETC | CNC or Not | Yes |

| Certification | CE, ISO9001 | Cooling system | Water cooling |

| Mode of Operation | Continuous | Feature | Low maintenance |

| Machinery Test Report | Provided | Video outgoing inspection | Provided |

| Place of Origin | Jinan,Shandong Province | Warranty time | 3 years |

Machine Video

The characteristic of 1210 Large Format Splicing Laser Marking Machine :

1. Three-chuck design (three pneumatic chucks)

1) Front, middle and rear chucks: solve the problem of pipe shaking and deformation when cutting long pipes

2) Support the shortest cutting of tail materials, effectively reducing material waste

3) The middle chuck is movable, effectively improving support and processing accuracy

2. 12-meter automatic feeding system

1) Adopts fully automatic pipe feeding rack + servo control system

2) Realizes continuous feeding of multiple pipes and whole-piece cutting

3) Saves labor, improves efficiency, and is suitable for large-volume order processing

3. Intelligent follow-up support system

1) Follow-up support during pipe processing to keep the pipe stable and prevent vibration

2) Improve cutting accuracy and protect the chuck and laser head

4. Can cut a variety of special-shaped pipes

1) Support cutting: round pipes, square pipes, rectangular pipes, elliptical pipes, hexagonal pipes, channel steels, angle steels, etc.

2) Optional groove cutting function to meet complex welding pretreatment requirements

5. High-power fiber laser

1) Optional MAX/RAYCUS/IPG brand lasers

2) Fast cutting speed, smooth cross section, no burrs

3) Low maintenance cost, stable operation

6. Special tube cutting CNC system

1) Intelligent graphic programming (compatible with Lantek, Tubest, Artube, etc.)

2) Support automatic edge finding, compensation, cutting simulation

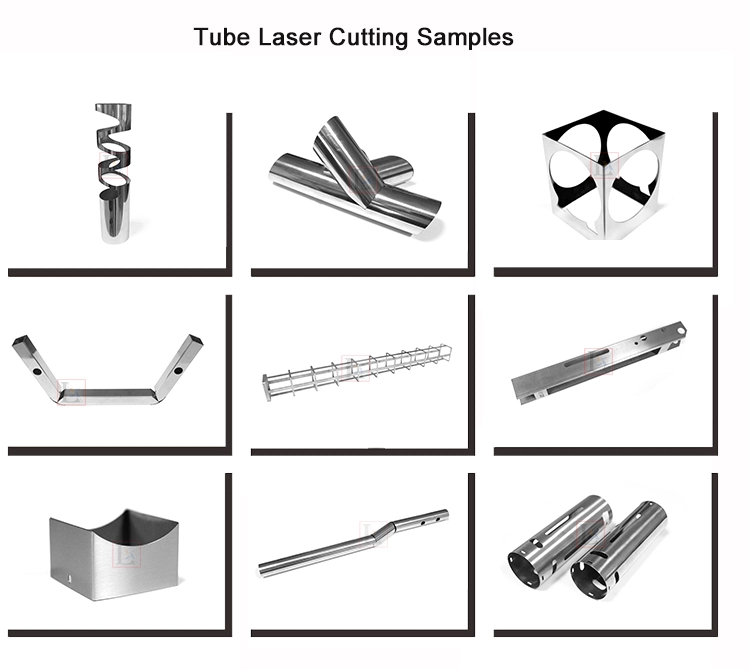

Cutting samples :

Service

1. Equipment customization: cutting length, power, chuck size, etc. can be customized according to customer needs.

2. Installation and debugging: provide on-site or remote guidance to ensure the normal operation of the equipment.

3. Technical training: operation training, software use, maintenance, etc., to ensure that customers are proficient in using the equipment.

4. Remote technical support: answer questions online and remotely assist in solving software or operation problems.

5. Spare parts supply: long-term supply of key accessories such as fiber lasers, cutting heads, chucks, etc.

6.Pre-sales consultation and technical support:

We have an experienced team of engineers who can provide customers with professional pre-sales advice and technical support. Whether it's equipment selection, application advice or technical guidance, we can provide fast and efficient help.

7.Quick response after sales

Provide fast after-sales technical support to solve various problems encountered by customers during use.

FAQ

Q: How big a tube can this laser tube cutting machine cut?

A: It supports a maximum length of 12 meters, a diameter range of Φ20mm–Φ350mm for round tubes, and supports opposite sides of ≤250mm for square tubes (larger specifications can also be customized).

Q: What are the advantages of the three-chuck design?

A: The three-chuck can effectively clamp and support long tubes, prevent shaking, and improve cutting accuracy. The middle chuck is movable, supporting short cutting of tail materials and saving materials.

Q: What types of tubes can be cut?

A: It supports round tubes, square tubes, rectangular tubes, oval tubes, waist round tubes, channels, angle irons, special-shaped tubes, etc. Bevel cutting function is optional.

Q: Is feeding and loading fully automatic?

A: Yes, it is equipped with an automatic loading system, which can hold multiple tubes at a time, automatically arrange, detect, and load, improve efficiency and save labor.

Q: What are the safety protection functions?

A: The equipment is equipped with laser protection cover, emergency stop button, safety interlock, electrical alarm system to ensure safe operation and meet CE standards (suitable for export).

Q: How to arrange installation, commissioning and training?

A: We provide "on-site installation and commissioning service" and provide system training for operators (online + offline optional). Overseas customers support video guidance and English operation manual.

Q: Can it be customized?

A: Yes! We can customize the loading rack size, cutting capacity, chuck form, automatic unloading system, etc. according to customer needs to meet the special processing requirements of different industries.