Laser Machine

-

Desktop Fiber Laser Marking Machine

Model: Desktop fiber laser marking machine

Laser power: 50W

Laser wavelength: 1064nm ±10nm

Q-frequency : 20KHz~100KHz

Laser Source: Raycus, IPG, JPT, MAX

Marking Speed: 7000mm/s

Working area: 110*110 /150*150/175*175/ 200*200/300*300mm

Lifespan of laser device: 100000 Hours

-

Enclosed Fiber Laser Marking Machine

1.No Consumables, Long lifespan:

The Fiber laser source can last 100,000 hours without any maintenance. If use correctly , then you do not need to spare any extra consumer parts at all. In normal, fiber laser could work for more than 8-10 years without extra costs except electricity.

2.Multi-functional Usage :

It could Mark un-removable serials numbers,logo, batch numbers, expiry info,etc. It could also mark QR code

-

Flying Fiber Laser Marking Machine

1). Long working lifetime and it can last over 100,000 hours;

2). Working efficiency is 2 to 5 times than a traditional laser marker or laser engraver. It is especially for batch processing;

3). Super quality galvanometer scanning system.

4). High accuracy and repeatability with galvanometer scanners and electronic controls.

5). Marking speed is fast, efficient, and high accuracy.

-

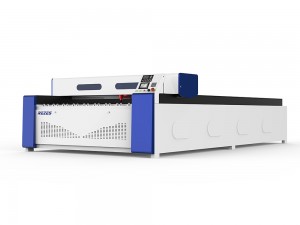

Metal&Nonmetal Laser Cutting Machine

1) Mixed Co2 laser cutting machine can cut metal, such as carbon steel, iron, stainless steel and other metals, and can also cut and engrave acrylic, wood etc.

1. Aluminum knife or honeycomb table. Two kinds of tables are available for different materials.

2. CO2 Glass sealed laser tube China famous brand (EFR, RECI), good beam mode stability, long service time.

4. The machine apply Ruida Controller system and it support online/offline work with English system. This is adjustable in cutting speed and power.

5 Stepper motors and drivers and with high quality belt transmission.

6. Taiwan Hiwin Linear square guide rails.

7. If need, you also can choose CCD CAMERA SYSTEM, it can do Auto Nesting + Auto Scanning + Auto position recognition.

3. This is machine apply imported lens and mirrors.

-

Metal Fiber Laser Cutting Machine With Exchange Platform

1. Adopt industrial heavy duty steel welding structure,under heat treatment,will not deform after long time using.

2. Adopt NC pentahedron machining, milling, boring, tapping and other machining processes to ensure high processing accuracy.

3. Configure with Taiwan Hiwin linear rail for all axis, to ensure durable and high precision for long time processing.

4. Adopt Japan Yaskawa AC servo motor, large power, stronger torque force, working speed is more stable and faster.

5.Adopt professional Raytools laser cutting head, imported optical lens, focus spot smaller, cutting lines more precise, higher efficiency and better processing quality can be ensured.

-

Metal Sheet Fiber Laser Cutting Machine

Metal fiber laser cutting machine is mainly used for cutting carbon steel, stainless steel,aluminum alloy, titanium alloy,galvanized plate, copper and other metal materials.Widely used in electrical power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, lighting hardware, display equipment, precision components, metal products and other industries.

-

Whole Cover Laser Cutting Machine

1. Adopt fully enclosed constant temperature laser working enviroment, makig sure the stable work more effective.

2. Adopt industrial heavy duty steel welding structure,under heat treatment,will not deform after long time using.

3. Owned the Japaness advanced cutting head controlling technology, and the automatic failure alarming protective display function for cutting head, using more safely, more convenient for adjustment, an cutting more perfect.

4. Fiber Laser Cutting Machine adopts the most sophisticated Germany IPG laser, combining Gantry CNC machine designed by our company and high strength welding body, after high temperature annealing and precision machining by large CNC milling machine.

5. High efficiency,fast cutting speed.photoelectric conversion rate about 35%.

-

Double Platform Metal Sheet & Tube Fiber Laser Cutting Machine

1. Our fiber laser cutting machine adopts the special CNC system of CypCut fiber laser cutting machine of Windows operating system. It integrates many special functions modules of laser cutting control, powerful and easy to operate.

2. The equipment can be designed to cut any pattern as needed, and the cutting section is smooth and flat without secondary processing.

3. Efficient and stable programming and control system, easy to operate, user-friendly, support a variety of CAD drawing recognition, high stability, with the use of wireless controller.

4. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. -

Backpack pulse laser cleaning machine

1. Non-contact cleaning, does not damage the parts matrix, which makes the 200w Backpack Laser Cleaning Machine very friendly to environmental protection

2.Precise cleaning, can achieve precise position, precise size selective cleaning;

3. Does not need any chemical cleaning liquid, no consumables, safety and environmental protection;

4. Simple operation, can be hand-held or cooperate with the manipulator to realize automatic cleaning;

5. Ergonomic design, operation labor intensity is greatly reduced;

6. High cleaning efficiency, save time;

7. Laser cleaning system is stable, almost no maintenance;

8. Optional mobile battery module;

9.Environmental protection paint removal.The final reaction product is discharged in the form of a gas. The laser of the special mode is lower than the destruction threshold of the master batch, and the coating can be peeled off without damaging the base metal. -

Laser Cleaning Machine

The laser cleaning machine is a new generation of high-tech product for surface cleaning.It could be used with no chemical reagents,no media, dust-free and anhydrous cleaning;

Raycus Laser source can last more than 100,000 hours, free maintenance; High electro-optical conversion efficiency (up to 25-30%), excellent beam quality, high energy density, and reliability, a wide modulation frequency;Easy operating system, supports language customization;

The design of the cleaning gun can effectively prevent dust and protect the lens. The most powerful feature is that it supports laser width 0-150mm;

About water chiller :Intelligent dual temperature dual control mode provides effective temperature control solutions for fiber lasers in all directions.

-

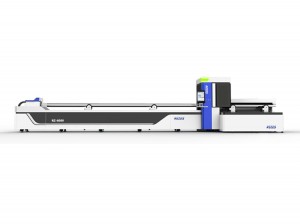

Metal Tube & Pipe Laser Cutting Machine

1.High rigidity heavy chassis, reducing the vibration generated during the high-speed cutting process.

2.Pneumatic Chuck Design:The front and rear chuck clamping design is convenient for installation, labor-saving, and no wear and tear. Automatic adjustment of the center, suitable for various pipes, high chuck rotation speed, can improve processing efficiency.

3.Drive System: Adopts imported bilateral gear-gear stripe transmission, imported linear guide, and imported double servo motor drive system, import high-precision linear module, to effectively guarantee the cutting speed and high precision.

4.The X and Y axes adopt high-precision servo motor, German high-precision reducer and rack and pinion. The Y-axis adopts double-drive structure to greatly improve the motion performance of the machine tool, and the acceleration reaches 1.2G, which ensures the high efficiency operation of the whole machine.